| Notable Features |

| |

|

Application of

“Ventonit” sprayed

plaster |

|

ISO

14000 certification |

|

On-site

sorting of waste |

|

Reuse of steel

hoarding |

|

Reuse of

large timber panels |

|

Recycled

waste water |

| Basic

Information |

| |

|

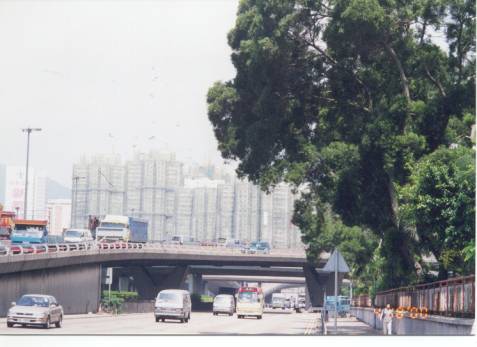

Location: San

Po Kong |

|

Building Type: Residential |

|

Contract Period:

July 1998 to Jan 2001 |

|

Gross

Floor Area: 179,100m2 (domestic), 9882m2 (non-domestic) |

|

Client:

City Team Development Limited |

|

Architect: Chows

Architects Limited |

|

Structural Engineer:

Fugro (H.K.) Limited |

|

E&M

Consultant: Carnival Consultant Limited |

|

Main Contractor: Hip

Hing Construction Co., Ltd |

|

Contract Sum: HK$1,300

million |

| Overview |

| |

|

The following major items were

executed under this contract: |

|

|

|

Demolition

of barracks including 12 existing buildings |

|

Foundation,

Site Formation Works, Construction of 12 nos. of residential

blocks, 1 carport block with shops, 1 elderly centre, 2

footbridge connections, and landscape gardens. |

|

|

|

|

|

|

|

| |

| The

demolition work was carried out by Hip Hing and commenced on

31 July 1998. There was no requirement for separation of

waste. On-site sorting of demolition waste was partially

executed. These materials included steel gates, windows,

reinforcement, which could be resold in the market for money.

Asbestos was also demolished separately according to the

building regulations. The rubble and other wastes were disposed

to the landfill. As for external works, some trees were

required to be preserved in the contract. |

| |

|

|

|

|

| |

| The

project mainly involved the construction of 12 towers of

residential blocks, a carport block with shops and an elderly

centre. Seven towers are 22 storeys and five towers are 30

storeys high. Traditional methods were adopted for this

project as the profile of the facades involved construction of

A/C hoods, which was not suitable to use steel form. |

| |

|

|

| Spray

Plastering |

|

|

|

The

low-waste technology, used for this project was “Ventonit”

sprayed plaster. For the wall surface, cement sand bedding was

applied prior to the application of sprayed plaster. As for the

ceiling surface, sprayed plaster was directly applied to the

concrete surface. The labour cost of sprayed plaster was HK$53

per square metre and the material cost was HK$27 square metre,

as at December 1999 prices. The cost of sprayed plaster is about

30% higher than traditional cement sand plastering. The

advantage of sprayed plaster is the guarantee of speed and

quality. It is getting popular in Hong Kong.

|

| |

|

|

| Contact

of Contractor

|

| |

| Hip

Hing Construction Co., Ltd. |

| 29/F,

New World Tower, 16-18 Queen's |

|

Road

Central, Hong Kong |

| Tel:

(852) 2525 9251

|

| Fax:

(852) 2845 9295

|

|

|

|

|

|

|

|

![]() |

|

| Waste Management |

| |

|

Waste

Management Plan |

|

| |

| For

the purpose of identifying opportunities and achieving

continual improvement on environmental performance through a

systematic approach, Hip Hing Construction Co., Ltd. has

documented and maintained an Environmental Management System

(EMS) conforming to ISO 14001:96 requirements. They have

obtained the ISO 14,000 certificate. Issues related to waste

management such as segregation of good and reusable material

as well as avoidance of unnecessary wastage resources are also

included in the EMS manual. |

| |

|

On-site

sorting of waste |

|

| |

|

On-site

sorting was partially performed. Chemical waste was stored

separately as required by regulations. Large rotten timber

panels and surplus reinforcement were transferred to the ground

floor by tower crane. There was 1 no. of plastic refuse chute

for each block. Although plastic refuse chute can reduce

noise, it is not durable. There was no separation of papers,

cans, lunch boxes, plastic conduits and rubble, etc. |

| |

|

|

| |

|

The

problems associated with separation of waste on site are the

extra resource and labour required as well as educating the

labourers. If on-site sorting of waste was to be carried out,

it was preferred to be sub-let to the subcontractor and to be

conducted centrally since space was available in the site.

|

| |

|

|

| |

|

Material

Control |

|

| |

| The

wastage was generally below 5%. The subcontractors were

generally required to supply both material and labour so that

they reduced the wastage of material as possible as they could.

In addition, a mock up floor/flat was used to control the use

of material for the remaining typical floors. |

| |

|

Use

of recycled materials |

|

| |

|

Waste

water was discharged to the waste water treatment plant

and then the treated water was distributed to the automatic tire

washer. |

|

| |

|

|

| |

|

Reusable

materials

|

|

| |

|

The steel hoarding

was used for the demolition contract as well as the

building contract. |

|

|

Large

timber panel was reused for working platform, etc. |

|

| |

|

|

|