|

|

| Notable Features | |

|

|

Loss-form

construction system (panel and corner unit) |

|

|

Precast facades and semi-precast balconies |

|

|

Aluminum

system formwork (slab and loss-form) |

|

|

Hardiwall partitions |

|

|

Precast door sets |

|

|

Spray-on-plaster |

|

|

| Basic Information | |

| Location: | |

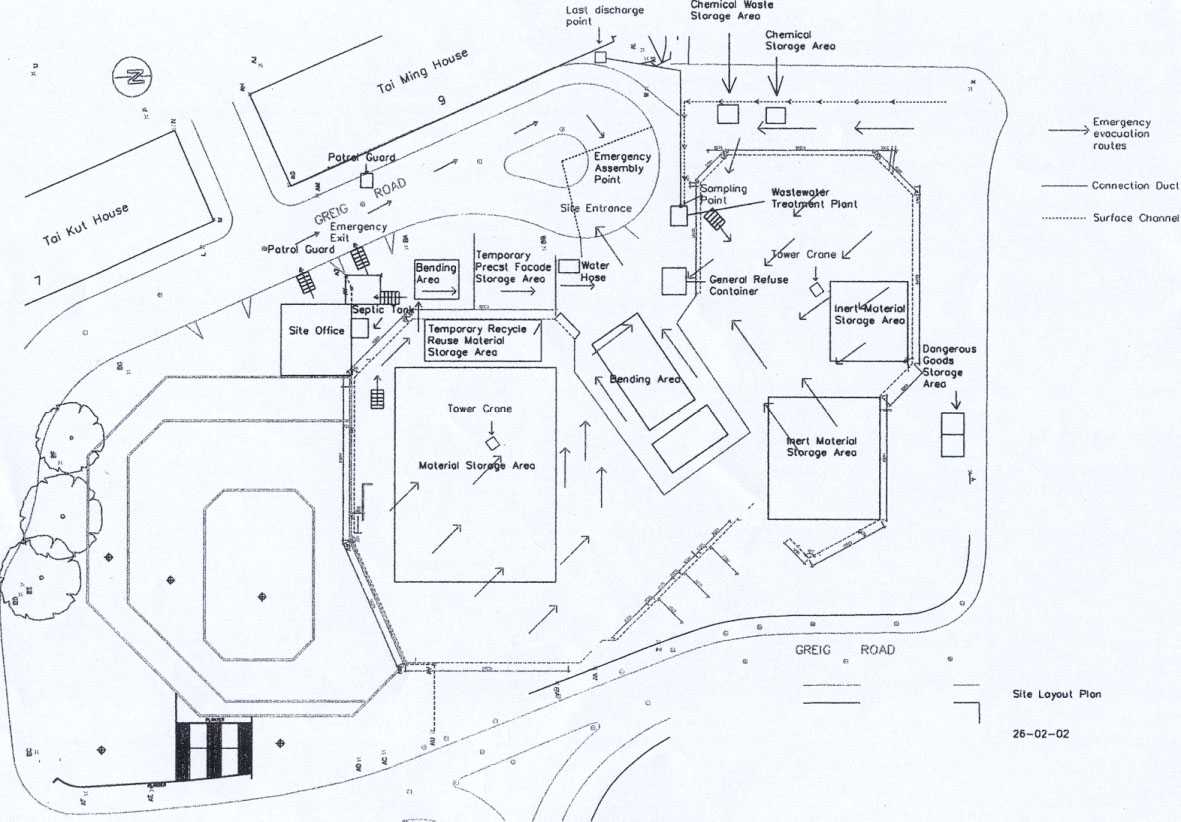

| Greig Street, Quarry Bay, Hong Kong. | |

| Building Type : | |

| Residential, private. | |

| Contract Period: | |

|

06/08/2001 – 31/03/2003 |

|

| Contract Sum : | |

| HK$497.5 million | |

| Site Area : | |

| 5,740 sq.m | |

| Gross Floor Area : | |

| 56,756 sq.m | |

| Typical Floor Area : | |

| 502 m2 | |

| Client : | |

| Braemar West Ltd. | |

| Client's Project Manager : | |

| Swire Properties Ltd. | |

| Architect : | |

| Wong & Ouyang (HK) Ltd. | |

| Structural Engineer : | |

| Meinhardt (C&S) Ltd. | |

| E&M Consultant : | |

| J. roger Preston Ltd. | |

| Quantity Surveyor : | |

| H.A. Brechin & Co. Ltd. | |

| Main Contractor : | |

| Hip Hing Construction Co. Ltd. | |

|

|

|

| . | |

| Overview | |

|

|

| The Orchards project consists of 2 towers providing 432 residential units, and 144 parking spaces. | |

|

|

| The residential building is 48 storeys high, with car park located at G/F, 1/F & 2/F, swimming pool located at 3/F and a clubhouse at 5/F. Sky Gardens are located at 17/F & 32/F. | |

|

|

|

|

|

|

. |

|

| Precast Construction Procedure | |

|

|

Position precast façade type A & B. |

|

|

Position lost form panels. |

|

|

Erect aluminum formwork (one side). |

|

|

Fix wall reinforcement. |

|

|

Close aluminum formwork. |

|

|

Formwork erection for beam and slab using aluminum formwork system. |

|

|

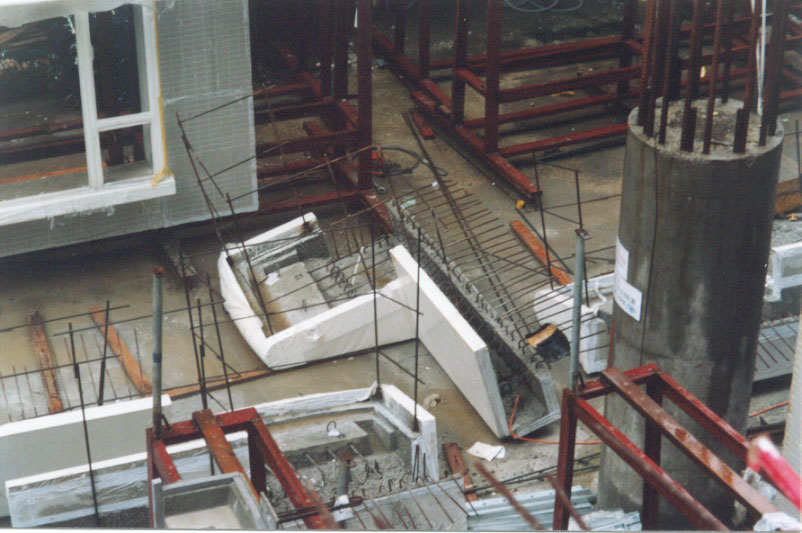

Position

precast balcony (propped below). |

|

|

Fix slab reinforcement. |

|

|

Cast concrete walls and slab. |

|

|

Remove wall formwork and props. |

|

|

GRC fixing will be installed after the sky garden completed. |

|

|

|

| Cost Comparison | |

|

The construction cost for conventional cast in-situ method was approximately HK$800/sq.ft, and for precast construction HK$816/sq.ft. The precast construction was approximately 1% higher than conventional construction method. |

|

|

|

|

|

|

|

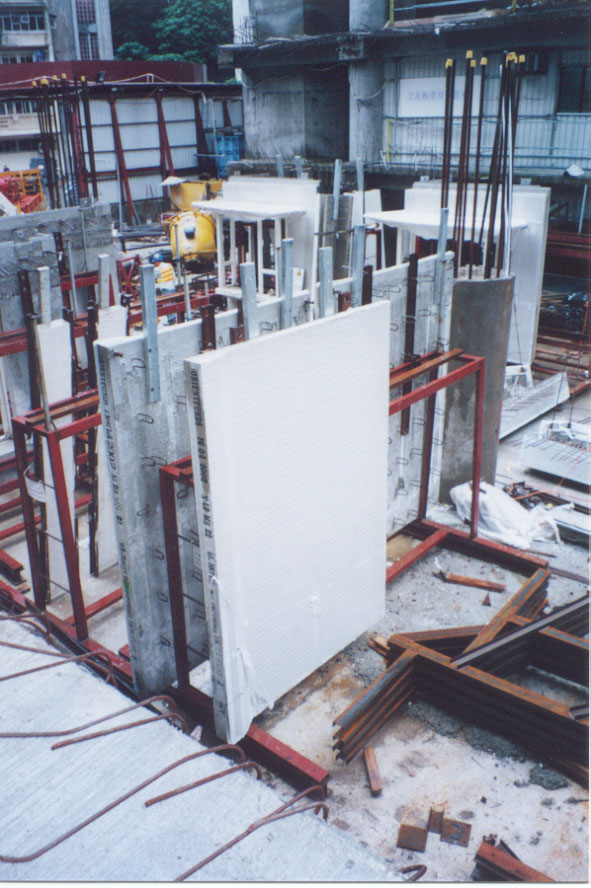

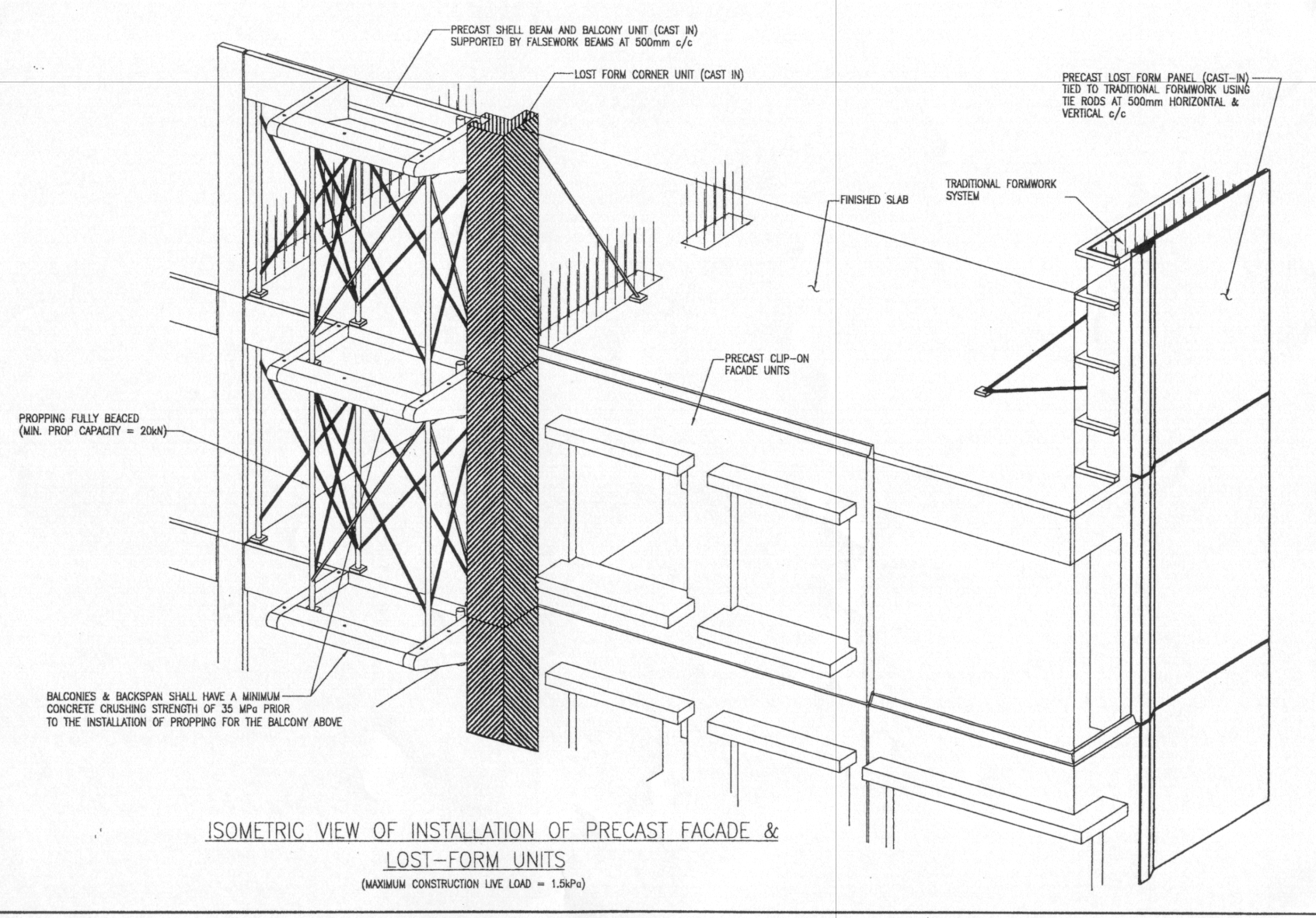

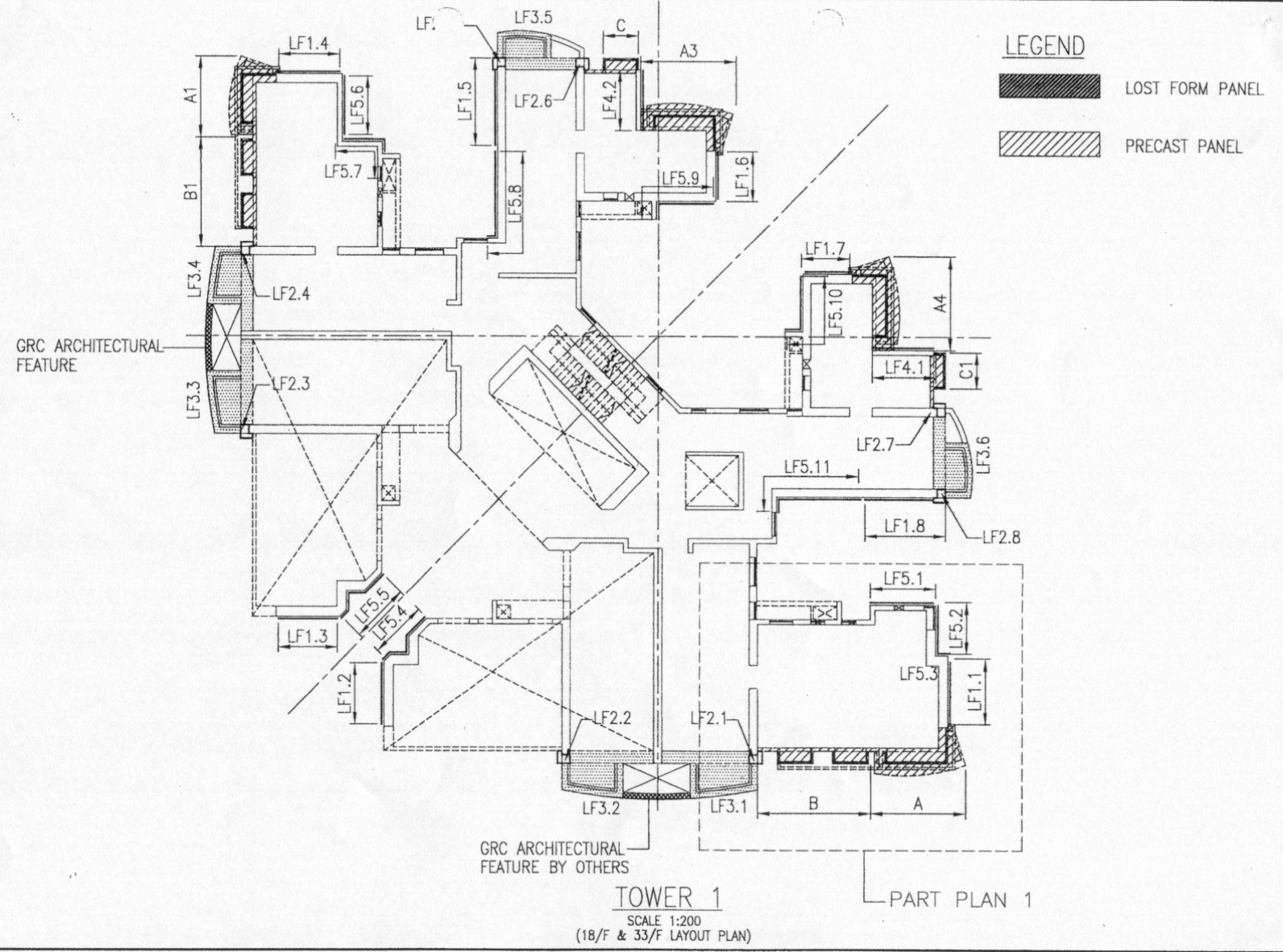

| Loss-form Construction System |

| Precast lost form panel and corner unit are used for the facades. The loss-form precast panels for the façade are used as permanent formwork together with aluminum formwork for the inside. The loss form panel is made of precast concrete and cladding at the factory and transported to the site. Tile filet is used for the installation of tile grout. The construction sequence is as shown in the figures: |

|

|

| 1.

Lost form

panel lifted to designate location. |

| 2. Brace lost form panel with kicker. |

| 3. Erect intend wall and slab formwork. |

| 4. Pour wall, slab and beam concrete. |

| The loss form panel dimensions are: 75mm thickness, and 2,534 high. |

| The loss form corner units are: 450mm x 550mm. |

|

|

This system minimizes the use of aluminum formwork for the external side, as it is a permanent formwork used as façade precast concrete cladding. Also the generation of waste on-site is reduced. |

|

|

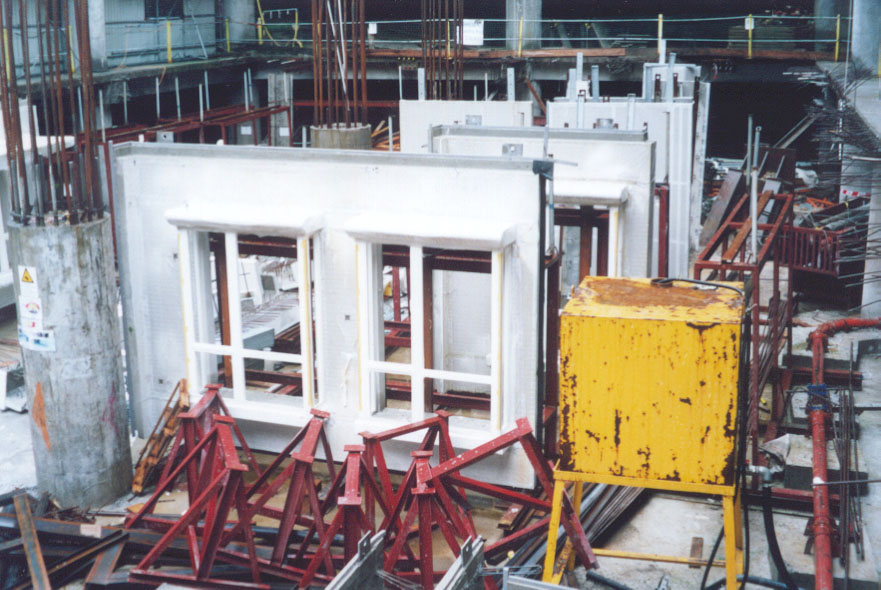

| Precast facades and Semi-prescast Balconies |

|

The precast facades are manufactured in China and transported to the site, stored in a storage area and lifted with a crane to the final position. Two types of precast facades are used in this project: type A, corner unit with external sun shading device, and type B with two window façade units. Type A precast façade is installed next to type B precast façade. Neoprene and metazeal was installed between the precast facades. |

|

Semi-precast

balconies |

|

|

|

Aluminum System

Formwork (Slab, Beams and Loss-form) |

|

Aluminum formwork was used for on side of the loss-form system and for the beams and slab construction. Aluminum formworks are easy to handle and can be reused over 100 times, and recycled after being reused. |

| Hardiwall Partitions |

| The hardiwall solid wall system reduces waste generated on-site as no wet trades are involved. It reduces structural design requirements due to lighter weight wall construction, and increases floor space due to thinner walls. Also it is up to 3 times faster to install than masonry wall. |

| Spray-on-plaster |

| Spray-on –plaster has advantages such as high productivity, low labour demand and less waste generation. |

| Contact of Contractor |

|

Hip Hing

Construction Co. Ltd. |

|

|