|

Notable Features |

|

|

|

Prefabricated concrete elements |

|

Flexible building system |

|

|

|

Basic Information |

|

|

|

Location

: |

|

Kassel, Germany |

|

Building Type : |

|

Office and

residential |

|

Architect : |

|

Alexander Reichel |

|

"Mitarbeiter"

: |

|

Johanna Reichel - Vossen, Stefan

Seibert, Caroline Ossenberg-Engels, Elke Radloff |

|

Tragwerksplaner

: |

|

Hobein, Kleinhans, Marx, Hochtief AG |

|

| . |

|

The Building System |

|

|

|

|

|

|

To allow for

maximum flexibility, the idea was to develop a 3D load-bearing structure that

could be extended in all directions and would provide functionally neutral

spaces. The openings between the structural elements could be filled with

various wall panels, depending on the usage required. The building was divided

into 3 different systems: |

|

|

|

The

load-bearing structure: reinforced concrete skeleton frame, filigree

floors, filigree walls. |

|

Timber framed elements: closed elements, elements with large window

strips, elements with small window strips, room-height glazing. |

|

Cladding elements: cladding to columns, beams and wall panels. |

|

|

Construction process: |

|

After

completion of the basic structure, timber framed elements were installed within

a period of 14 days. The elements were supplied ready clad on all faces with

cement-bonded chipboard. The external insulation to the load-bearing columns and

beams was added after the infill panels had been fixed in position. |

|

|

|

|

|

|

![]() |

|

|

Overview |

|

|

|

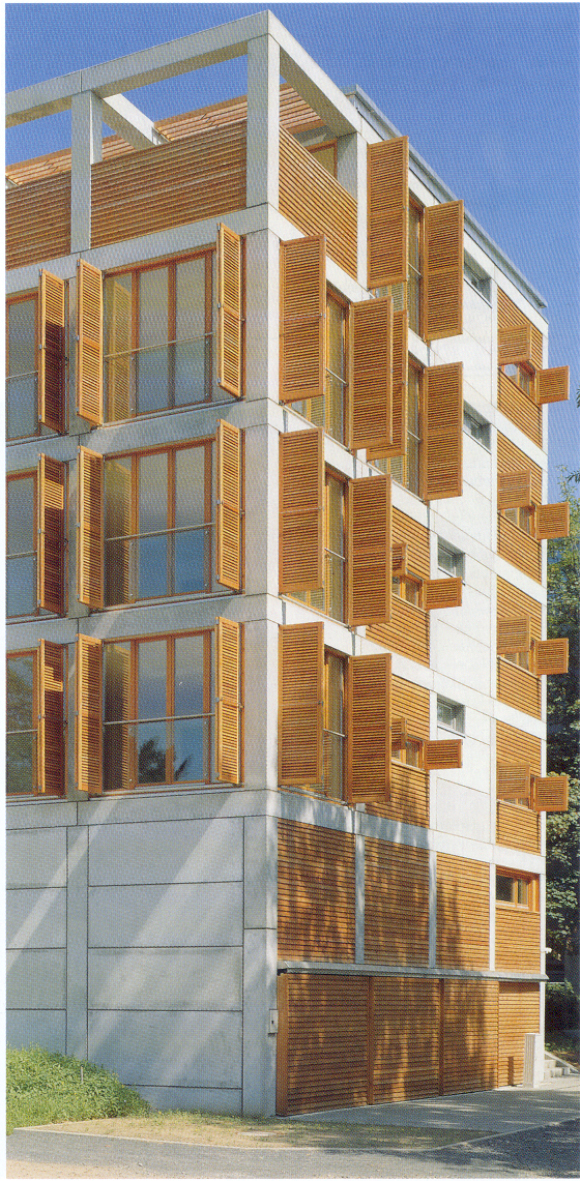

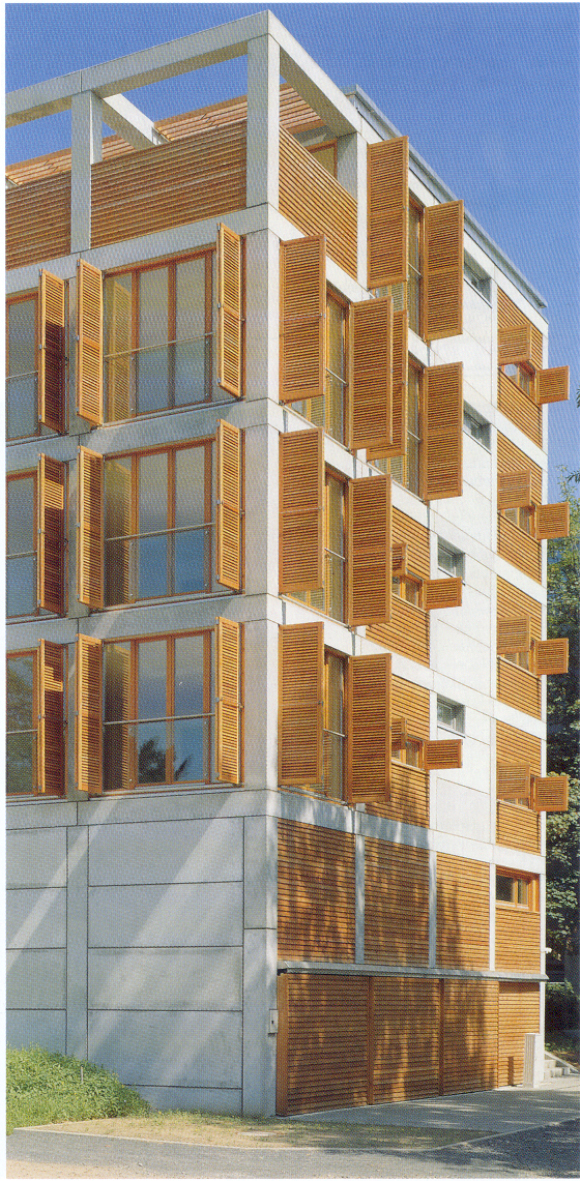

The project

brief required a maximum flexibility in the use and layout and possible

adaptation to various site conditions (accommodation to 9 different sites). The

dimensions of this building were 13.52 x 12.30 x 15.40 m high. |

|

|

|

|

|

Prefabricated

Elements |

|

|

|

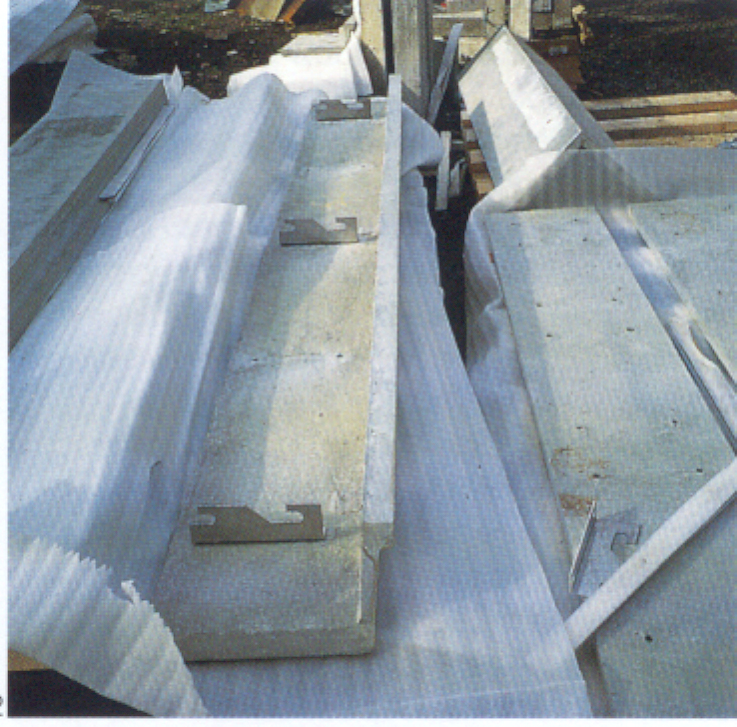

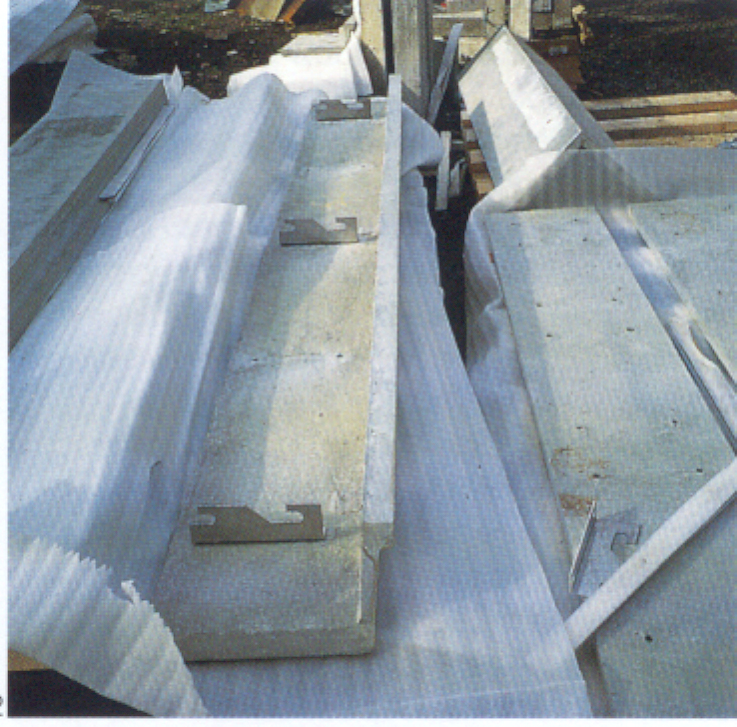

A maximum

number of elements were prefabricated and delivered to site ready for assembly.

The additional time and effort invested in the detailing would be balanced out

by a quicker and simpler assembly process on site. |

|

|

|

|

|

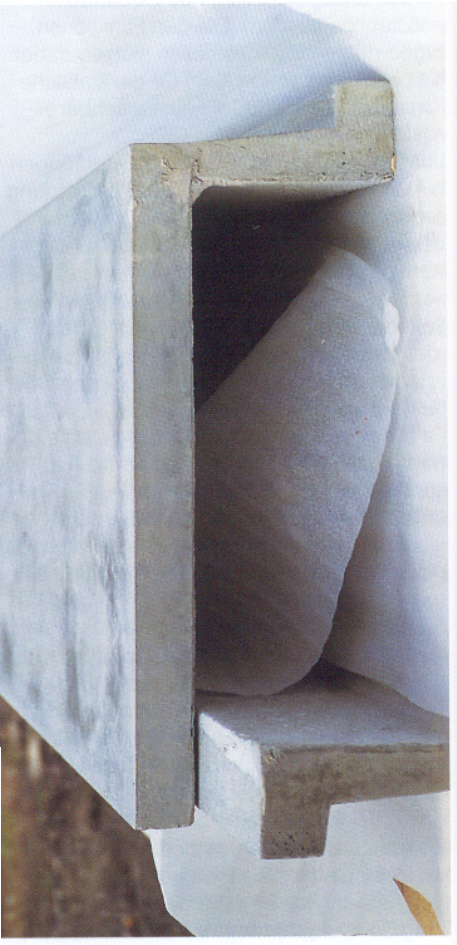

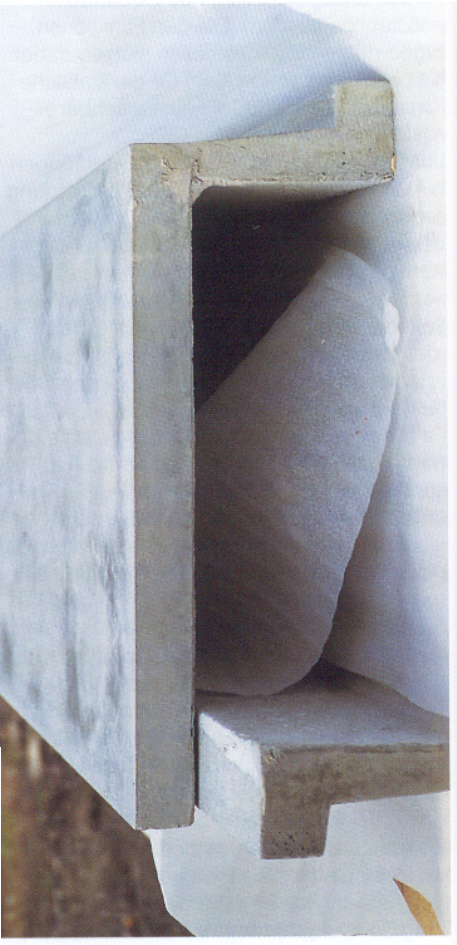

Glass-fibre-reinforced

concrete was used for the precast concrete cladding to avoid corrosion of the

reinforcement and allowed the use of elements with slender dimensions, lower

weight and smooth, even surface and sharp arises. Also the thickness was only 3

cm. It also enabled the thickness of the wall elements to be reduced and

therefore the volume of materials delivered to site and structural loading were

minimized, allowing economic advantages. Glass-fibre-reinforced concrete

consisted of fine-grained cement concrete (aggregates < 4 mm) in which

alkali-resistant glass fibres (roughly 2-4 mm long) were mixed. The fibres

provided reinforcement against tensile stresses and cracking. |

|

|

|

The elements

used in this project were generally 3.0 x 1.7 m and 3 cm thick. The clips

consisted of 2 U-shaped interlocking stainless-steel components allowing the

construction to be adjusted horizontally and vertically. The cladding elements

were fixed to the U-sections by means of inbuilt hooks. All precast elements

were subjected to hydrophobic treatment for water-repellent. |

|

|

|

|

|

|

|

Sources |

|

|

|

Detail, Serie 2001, No.4, Modular systems,

p674-679 and p700 |

|

|

|

|

|

|