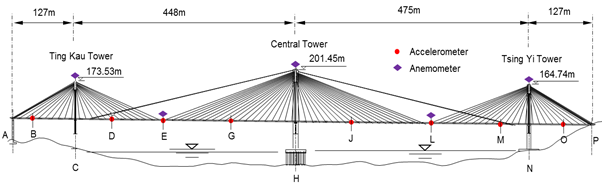

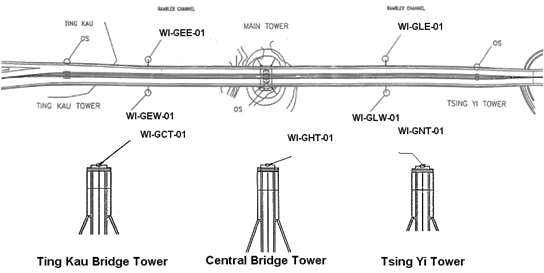

Figure 1 TKB and layout of accelerometers on bridge deck

Structural Health Monitoring Systems

After the completion of the bridge construction, a sophisticated long-term monitoring system, called Wind And Structural Health Monitoring System (WASHMS), has been devised by the Highways Department of the Hong Kong SAR Government to monitor the structural health and performance of the three bridges in HK under in-service condition.

The WASHMS is composed of six integrated modules: sensory system (SS), data acquisition and transmission system (DATS), data processing and control system (DPCS), structural health evaluation system (SHES), structural health data management system (SHDMS), and inspection and maintenance system (IMS). The SS comprises a variety of sensors and their interfacing units for the measurement of physical parameters of a bridge and its surrounding environment. The DATS comprises two categories of equipment, namely data acquisition units and network systems for the acquisition, processing, temporary storage, and transmission of signals. The DPCS refers to the hardware and software of a high-performance computer system for the execution of system control, system operation display, bridge operation display, and processing and analysis of data. The SHES, which is the core of an SHM system, is a high-performance computer system equipped with appropriate software tools for the execution of inter-solver finite element analysis, sensitivity analysis and model updating, bridge feature and response analysis, diagnostic and prognostic analysis, and visualization of analyzed results. The SHDMS is composed of a high-performance computer system, a data repository system, and a data warehouse management system for the storage and retrieval of monitoring data and analysis results. The IMS is a laptop-computer-aided portable system for the inspection and maintenance of sensors, data acquisition units, data transmission networks, and display facilities. By implementation of WASHMS, all data acquired from sensor system will be collected and digitized by the data acquisition units and finally transmitted into the monitoring center for processing and management and for further structural health evaluation.

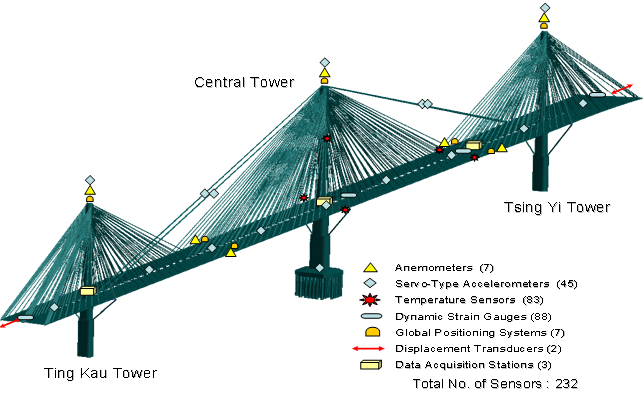

The sensors are categorized into four groups: (i) sensors for monitoring of environmental loads and/or status, which include anemometers (three-dimensional ultrasonic type and two-dimensional propeller type), temperature sensors (for the measurement of temperatures in respective air, asphalt pavement sections, structural concrete sections, structural steel sections, suspension cables, and stay cables), corrosion cells, hygrometers, barometers, and rainfall gauges; (ii) sensors for monitoring of traffic loads, which include dynamic weigh-in-motion stations, digital video cameras, and dynamic (weldable foil type) strain gauges; (iii) sensors for monitoring of bridge characteristics, which include fixed and removable/portable servo-type accelerometers, global positioning systems, level sensing stations, and dynamic strain gauges; and (iv) sensors for monitoring of bridge responses, which include dynamic strain gauges, static (vibrating wire type) strain gauges, displacement transducers, global positioning systems, tiltmeters, fixed servo-type accelerometers, buffer sensors, bearing sensors, and elastomagnetic sensors. In the cable-stayed Ting Kau Bridge, there are 24 uni-axial accelerometers, 20 bi-axial accelerometers, 1 tri-axial accelerometer, 7 anemometers (ultrasonic-type and propeller-type anemometers), 2 displacement transducers, 83 temperature sensors, 88 strain gauges (66 linear strain gauges and 22 rosette strain gauges) and a weigh-in-motion sensing system (with 6 sensors).

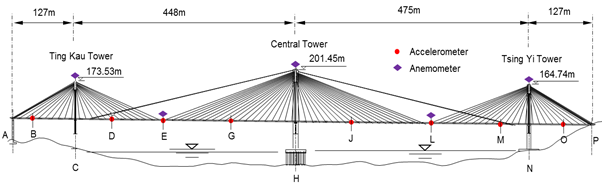

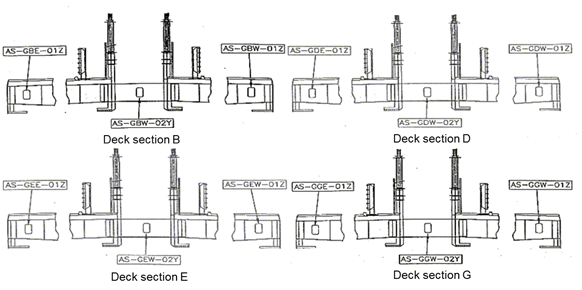

The accelerometers were installed at the deck of two main spans, the Ting Kau side span deck, the Tsing Yi side span deck, the longitudinal stabilizing cables on the two main spans, the top of the three towers, and the base of central tower to measure the dynamic characteristics of the bridge. The layout of the accelerometers along the bridge deck and deployment at deck sections on the TKB are shown in Figure 1 and Figure 2. The geometry configuration of accelerometers on bridge deck is shown in Figure 3. Accelerometers (2, 5, 8, 11, 14, 17, 20, and 23) installed in central crossgirder measure the transverse acceleration, others measure the vertical acceleration. The sampling frequency was 25.6 Hz, with unit m/s2.

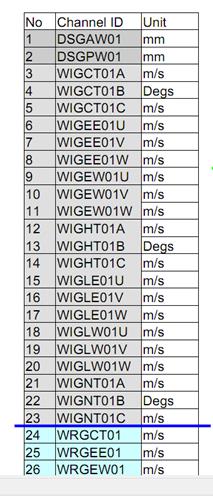

The anemometers were installed at the deck level of the two main spans and the top of the three towers to measure the wind speed and direction. Figure 4 shows the deployment of anemometers on the bridge deck and towers. According to the figure, there are four anemometers were installed on the bridge deck and three anemometers at the top of the towers with sampling frequency of 2.56Hz. Figure 5 is the list of channels for the anemometers and corresponding units.

The displacement transducers were installed at the road expansion joints at the Ting Kau abutment and Tsing Yi abutment to measure the deck longitudinal movement. The temperature sensors were installed at the deck of the two main spans and at the central tower to measure the temperature in steel sections, concrete sections and asphalt pavement sections. The strain gauges were installed at the deck girders, deck plates and bearings to measure the peak stress, stress-cycle and the bearing performance. The weigh-in-motion sensing system (bending plate type) was installed at the carriageways near the Tsing Yi abutment to measure the traffic flow and loads. There are three data acquisition outstations on the bridge. The layout of sensory system and data-acquisition system are shown in Figure 6.

Figure 1 TKB and layout of accelerometers on bridge deck

Figure 2 Deployment of accelerometers on four deck sections

Figure 3 Geometry configuration of accelerometers on bridge deck

Figure 4 Deployment of anemometers on the bridge deck and towers

Figure 5 List of channels for anemometers

Figure 6 Layout of sensory system and data-acquisition system